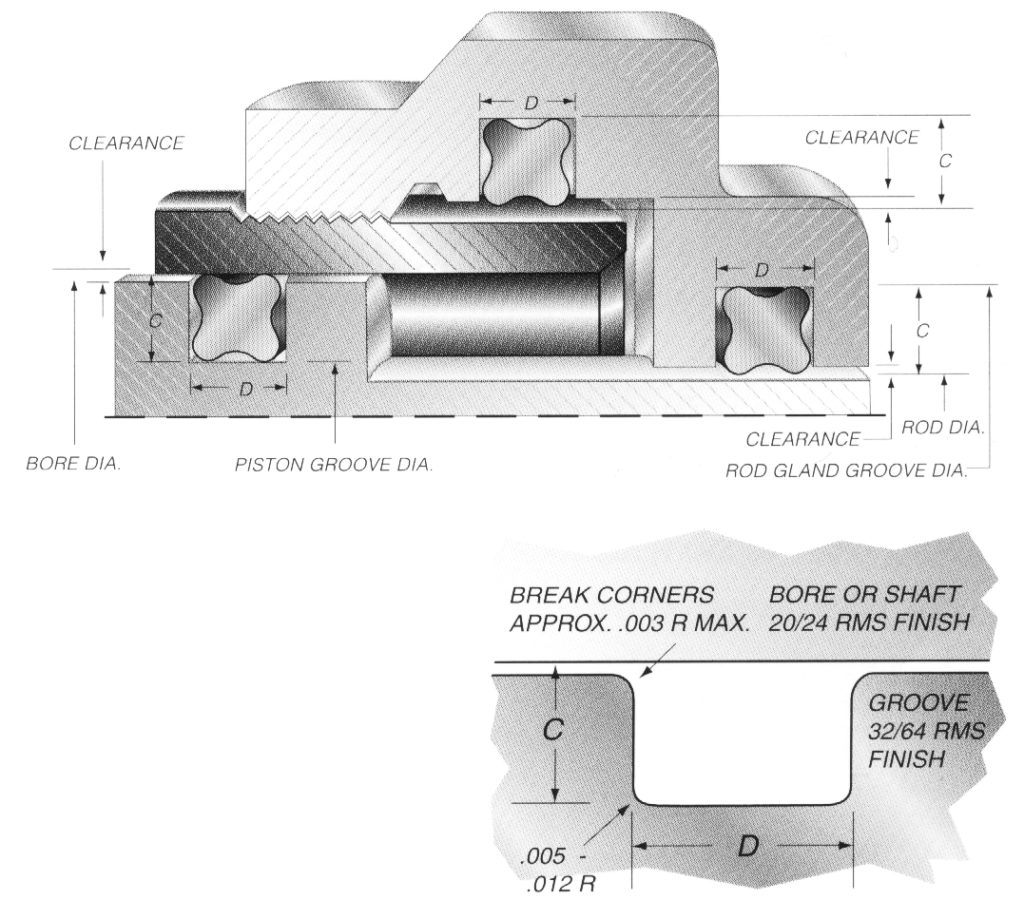

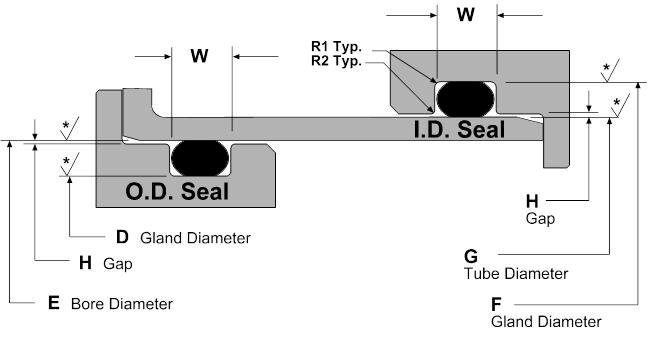

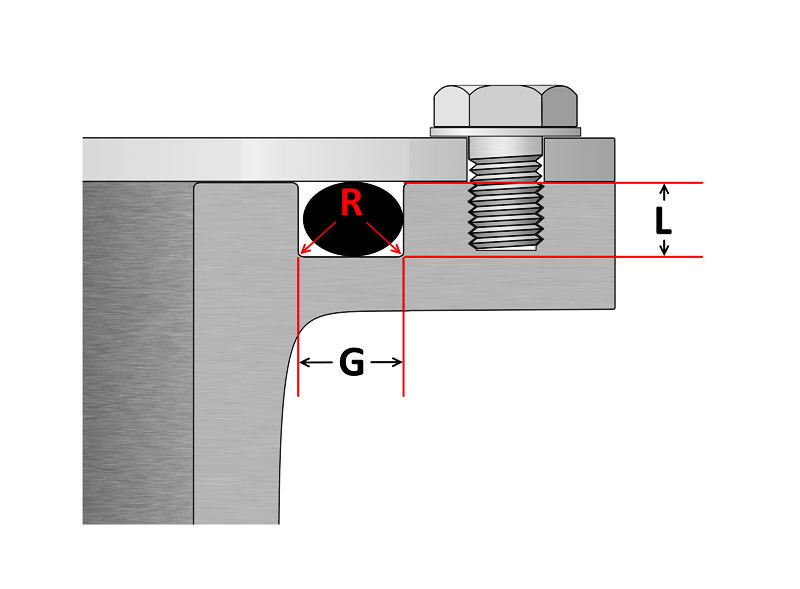

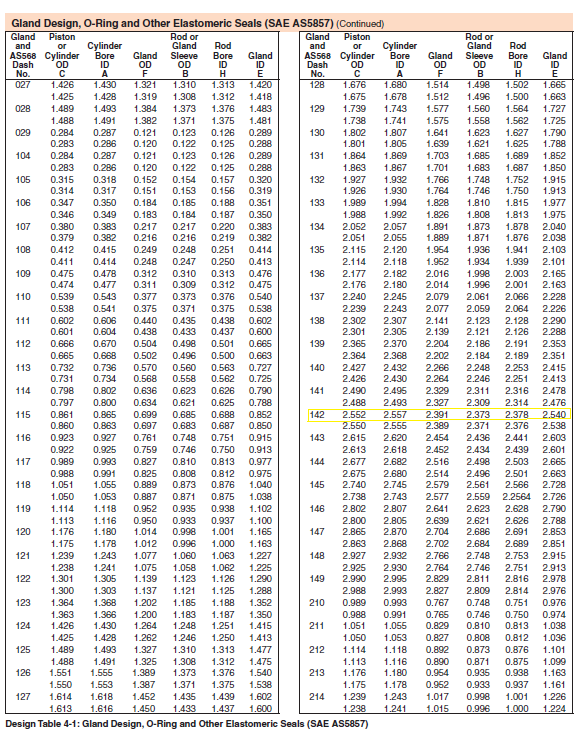

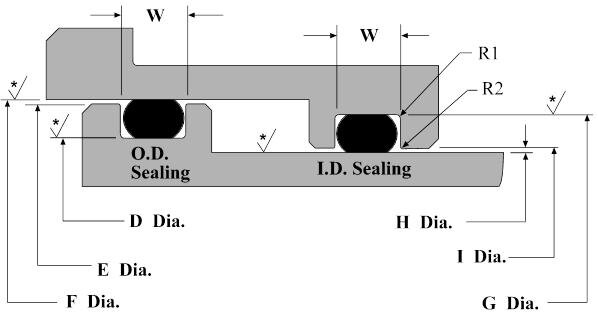

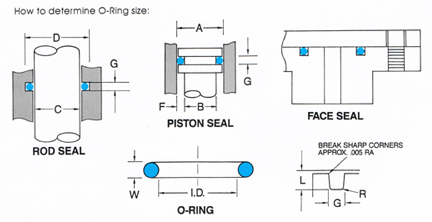

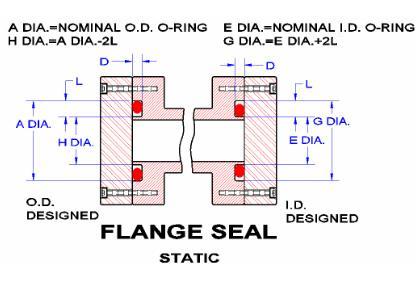

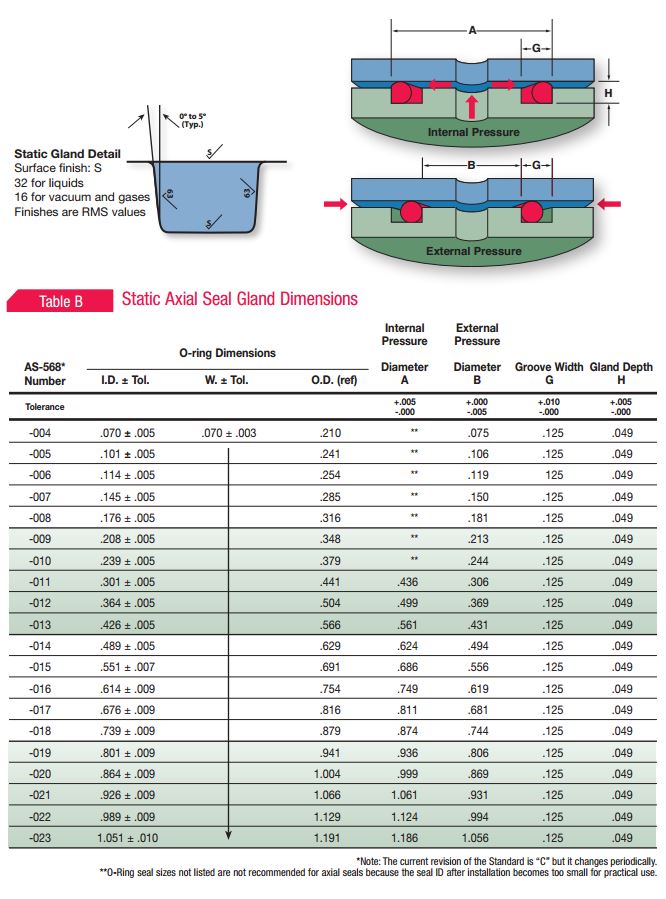

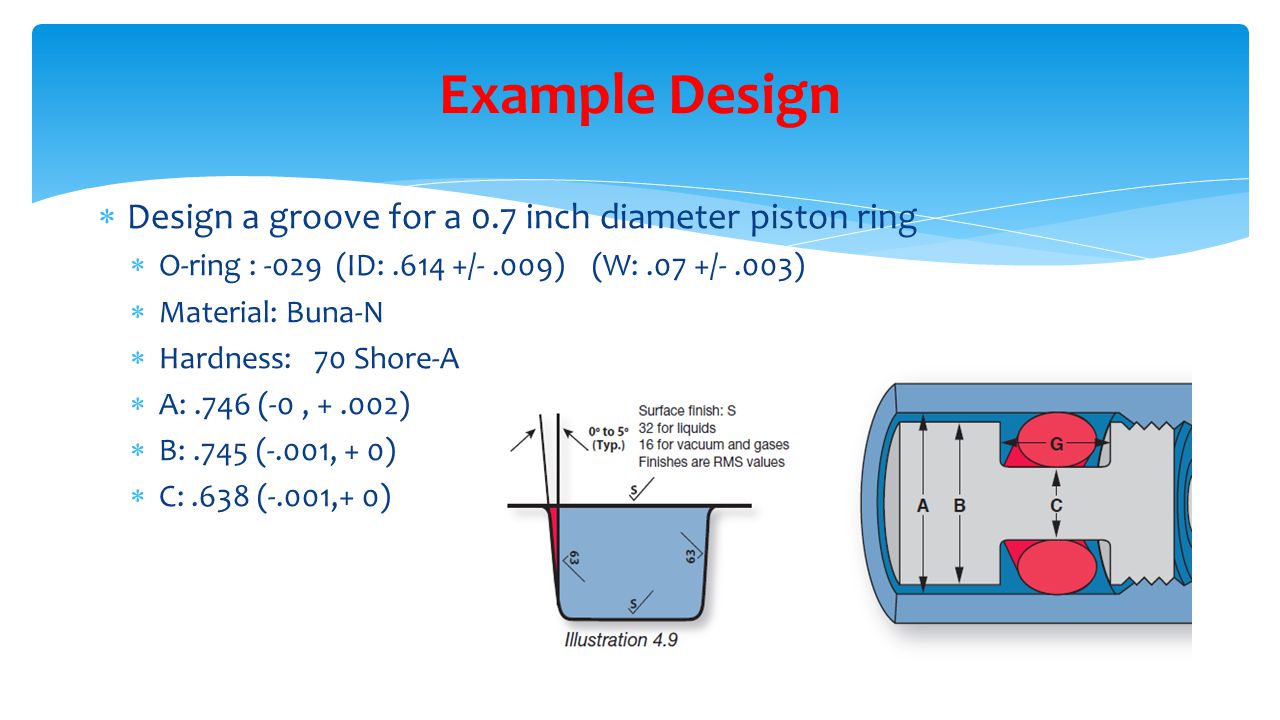

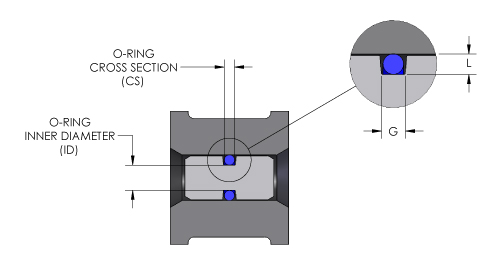

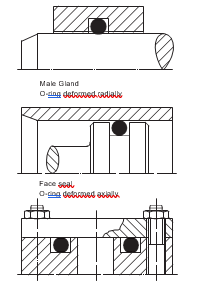

Call Us Seal & Design Canada Toronto, Ontario (416) Toll FreeGroove Design Technical Data Static ORing Axial (Face Seal) Glands Gland Squeeze Groove Width Groove;1 Male or Plug the Oring groove is located on a plug which is inserted into the housing or cylinder (fig 123) 2 Female or Tube the Oring groove is located in the housing or cylinder and a tube is installed through the Oring lD (fig 124) Male or Plug Seal design is based on the following factors (refer to fig 123) Bore Diameter (A)

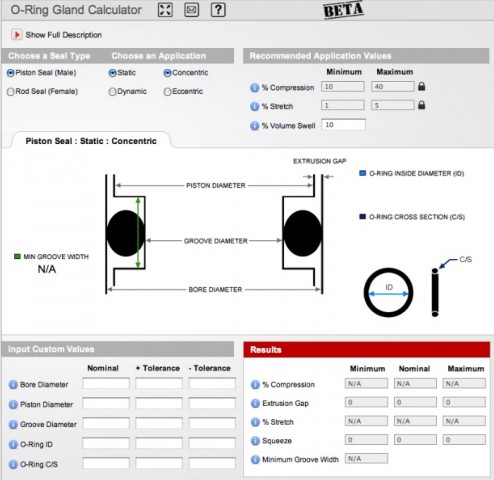

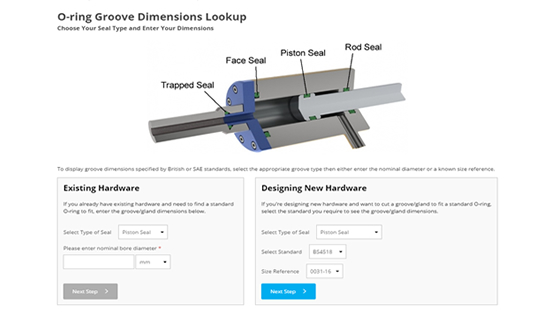

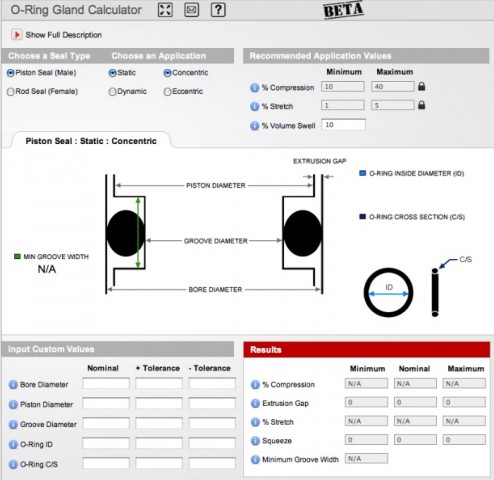

New Gland Calculator Tool At Applerubber Com Official Apple Rubber Blog

Metric o-ring face seal groove design

Metric o-ring face seal groove design-The ORing Store LLC ORing Groove Chart ORing Cord Stock OSK™ Assorted ORing Kits OSK™ ORing Repair Kits OSK™ Hydraulic Seal Kits OSK™ Air Nailer ORing Kits ORing Lube ORing Tools AS568 ORings (Inch) Metric ORings (mm) OSK Pool, Spa & Pump Orings Hydraulic Seals Inch ORing Glue & Thread Sealant Vulcanized ORings ORing Splice Kits & Tools Hydraulic SealsAS568B CS Depth Inches % Liquids Gases Radius004 to050

1

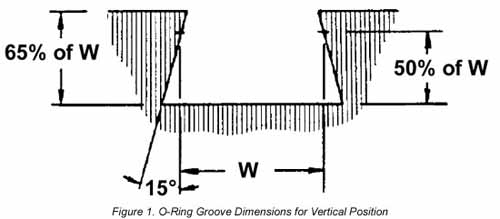

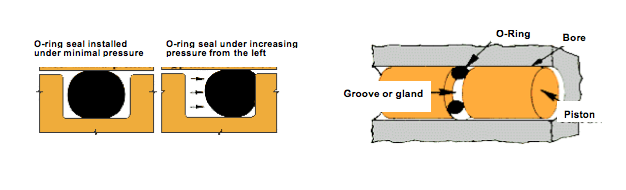

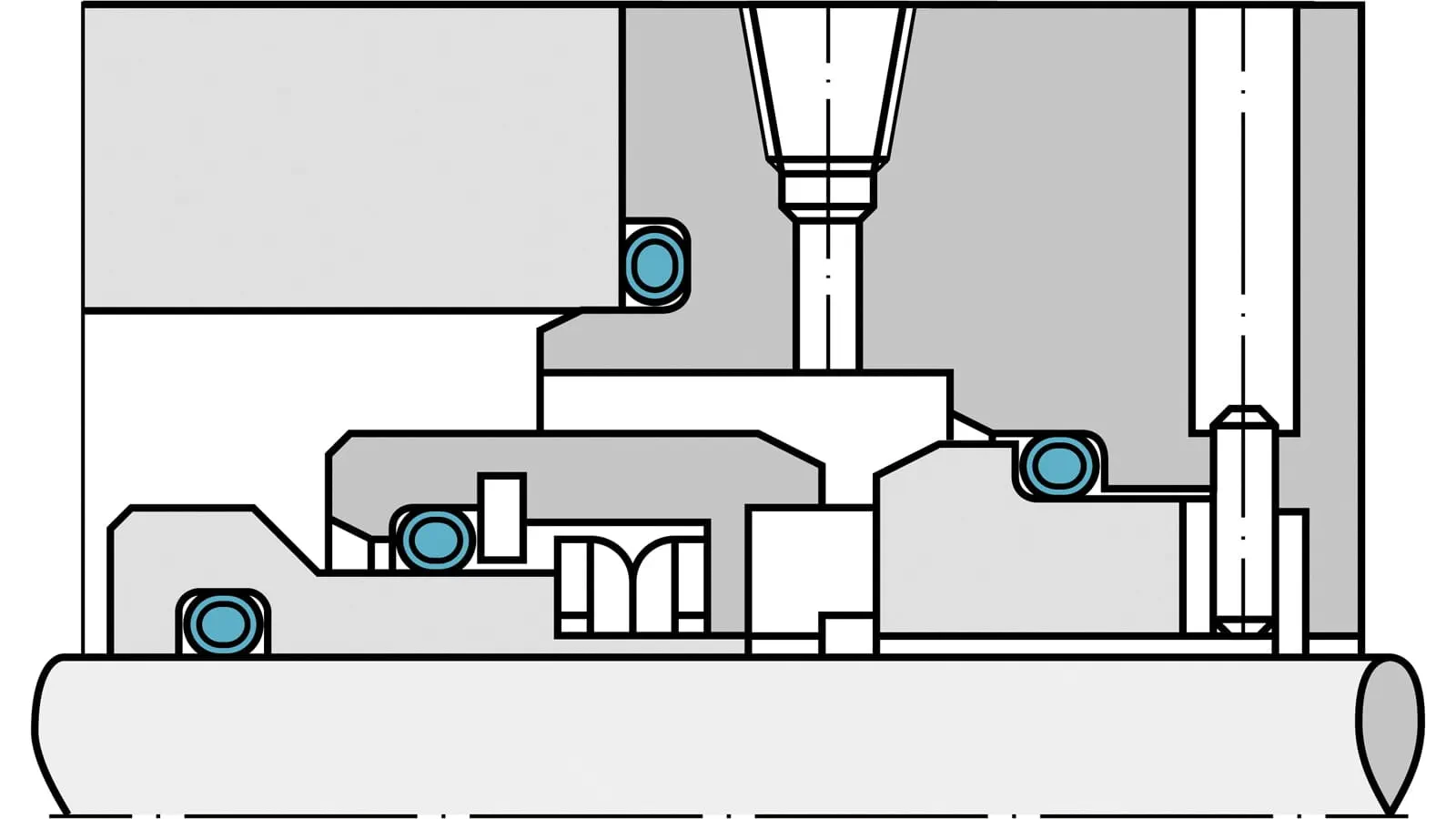

Our oring groove design guides list default oring groove dimensions for the most basic applications and are intended to be used with the following oring groove design considerations to engineer on oring gland to optimize specific application performance The wrong size groove makes even the best oring underperformThe Oring may be housed in a groove (rod seal) in the cylinder wall instead of a groove in the piston surface (piston seal) without any change in design limitations or seal performance Oscillating A valve spindle is an example of an oscillating applicationTested in face type Oring seals using grooves that provided 15%, 30% and 50% compression For vertical Oring applications (as a chamber), it is desirable to use an undercut groove similar to that shown in Figure 1 The Oring is held firmly in place and has no tendency to drop out of the groove when the chamber is open Figure 1

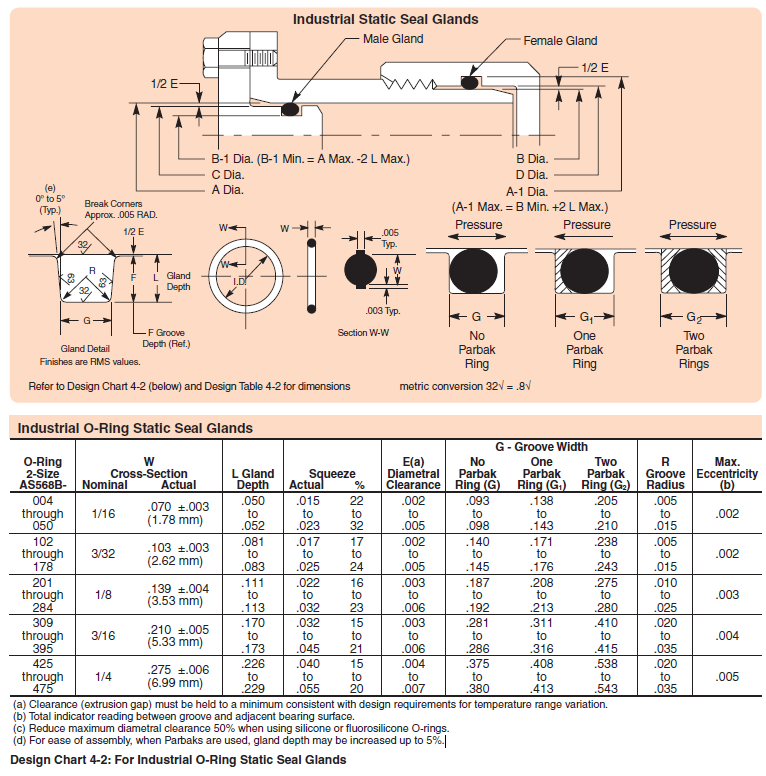

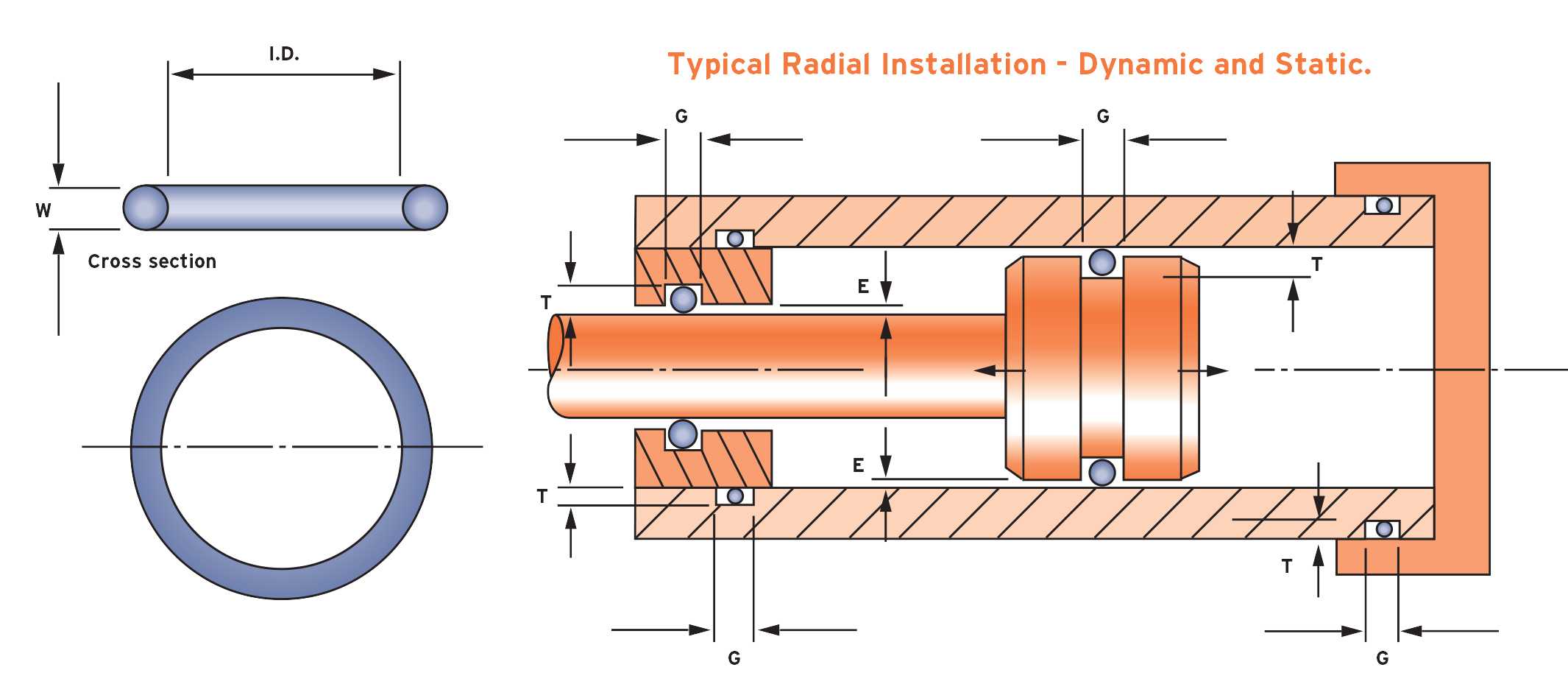

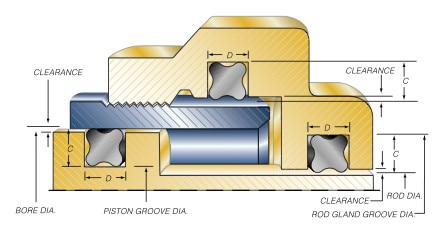

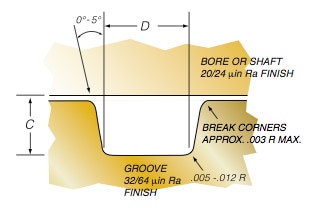

The oring gland design is more complex for radial seals and requires both the piston and the bore to have precise geometry The bore and the piston have to be concentric to one another One of the faces will be completely smooth and one will have an oring groove cut into it;AS568B STANDARD ORING GROOVE DESIGN Contact Us For Assistance Or Samples Click Here and contact us today to receive a quote or if you have any questions regarding sizing × Dismiss alert The three main types of standard groove designs are Industrial Static also called Radial, Industrial Reciprocating also called Dynamic, and Face Seals alsoStatic Radial ORing Gland Design In a static radial seal application the oring is squeezed between the inner ID and the outer OD surfaces of the oring, with no relative motion between parts of the gland that come in contact with the oring The table below lists recommended dimensions for static radial seal glands by AS568A oring dash

To compress an Oring of 533 mm thickness by %, approx 5 N per mm of sealing length is required for a hardness of 70 Shore A resp 7 N/mm for 80 Shore A To facilitate assembly, the diameter of the Oring groove is usually selected somewhat larger than the diameter of the Oring This keeps the Oring in the groove during assemblyGeneral Engineering Menu ORings Suppliers Molded ORings Services ORings Design Guidelines, Specifications, Materials An Oring , also known as a packing , is a flexible gasket in the shape of a loop;Now, follow the steps below to design your own oring seal and oring groove Step 1 Choose your rubber properties by going to our Oring Material Guide section Step 2 Make sure that the material you choose will withstand the temperature of your system by going to this rubber temperature range chart Step 3

Quad Ring Groove Design Daemar Inc

O Rings Designing

The groove is in the 'ceiling' of the application, so I want that the oring is compressed into the groove to prevent it from falling out when the seal is opened The inside circumference needs to be sufficiently small to provide space for the oring to be squeezedClick here for more information on face seal groove design Note the ORing inside diameter for the next step Calculate the Seal Stretch Using Equation 1, calculate the installed seal stretch If the installed seal stretch is greater than about 3%, you may have to select the next larger ORing or require a custom ORing for your applicationThe ERIKS Oring design calculator features the calculation of • oring dimensions for the use in a specific groove • groove dimensions for the use of a specific oring • evaluation of both, any combination of oring and groove for axial seals with inner or outer pressure, piston seals and rod seals

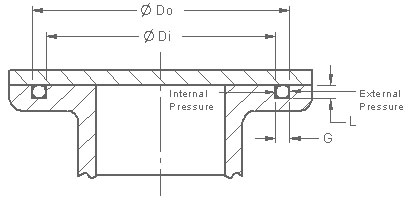

O Ring Installation Design And Specification Static Flange Application Engineers Edge

Static O Ring Design Chart Marco Rubber Plastics Custom O Rings Supplier

XRing Seals and high performance ORing material groove design follows the same principals as basic ORing applications, although require even more attention to design adjustments for specific application environments for optimal sealing performance and lifeERIKS standard ORings and load them also into your created design info chemical volume swell (%) cross section diameter (mm) ISO 3601 free Calculate Results Reset calculatorDesigning Oring seals for low pressures, therefore, is not simply a matter of reducing the amount of squeeze it involves a delicate balancing of material hardness, dimensional tolerances, stress relaxation, and friction characteristics Material Hardness The initial phase of designing a lowpressure Oring seal is the same

4 Common Mistakes In Designing For An O Ring Axial Face Seal Hot Topics

Anyone Have Experience Designing An Asymmetrical O Ring Groove Under A Bolt Head Mechanical Engineering General Discussion Eng Tips

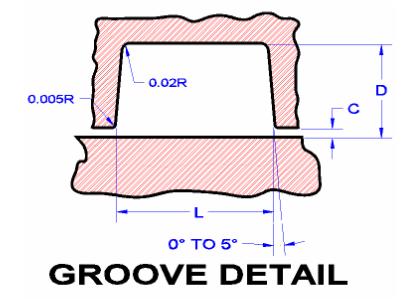

When designing such a seal to receive a standard Oring, the inside corner radii of the groove should be at least three times (ideally six times) the crosssection diameter of the Oring to avoid overstressing the ring or causing corner creases that would potentially leakORing Handbook Parker Hannifin ORing Diision Europe ORing Handbook Parker Hannifin ORing Diision Europe Preamble Sealing technology by ParkerPrädifa The Engineered Materials Group of the Parker Hannifin Corporation is the worldwide leader in the field of designing, developing and manufacturing sealing systems, vibration dampers, EMIDesign dimensions for oring installation Orings are normally used as seals in several ways, and dimensions of the groove or gland will also vary with the cross section of the ring, the type of

O Rings An Overview Sciencedirect Topics

Http Practicalmaintenance Net Wp Content Uploads Working Design Considerations And Maintenance Of O Rings Pdf

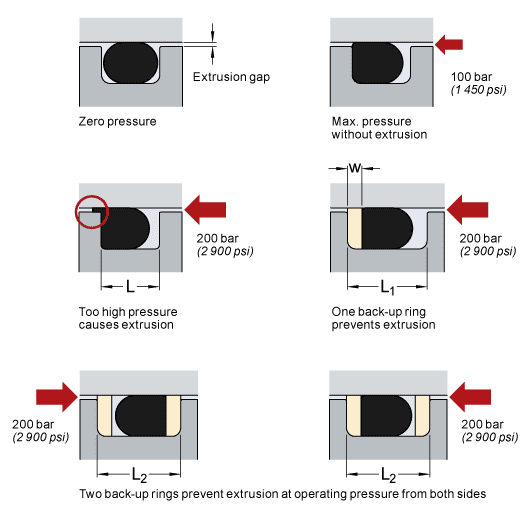

For additional information about Oring and backup ring materials, refer to Materials and about extrusion, refer to Gap extrusion Housing groove width To accommodate the additional backup rings, the Oring groove width L needs to be increased to L1 for one backup ring or L2 for two backup rings The groove width dimensions are listed inDesign Table 42 Gland Dimensions for Industrial ORing Static Seals, 1035 Bar (1500 psi) Max Gland Dimensions for Industrial ORing Static Seals, 1035 Bar (1500 psi) Max† A A1 B B1 C D G† ORingDesigning the parts of an application where orings will be applied is broadly termed "oring groove design" In order to seal properly, the oring has to deform in the application by being compressed and stretched in any number of ways The design of the groove where the oring sits plays a major role in how the oring performs its sealing role

Design Of Oring Seals Design Of Oring Seals

O Ring Groove Design Standard As568b Seal Design Inc

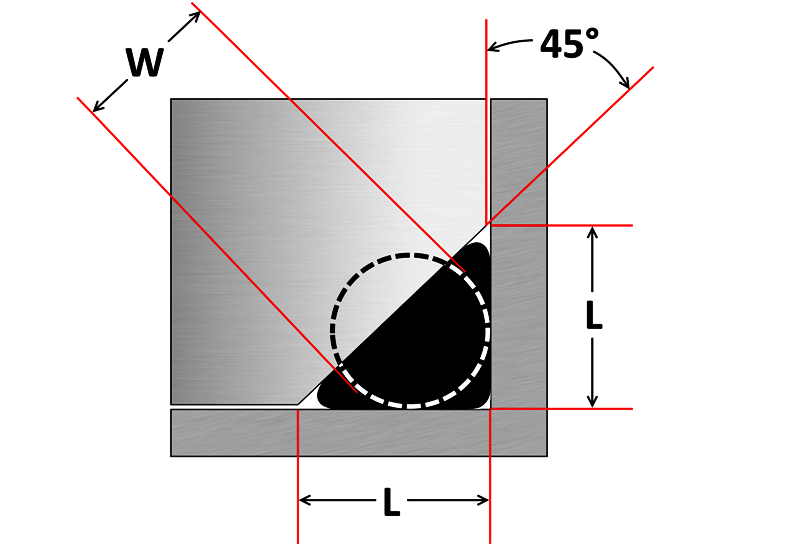

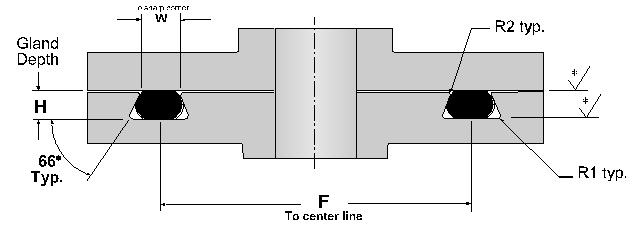

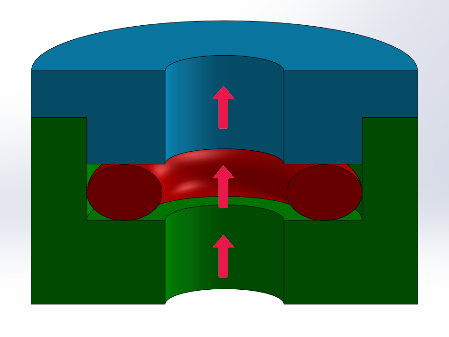

O'ring Groove Design As important as the o'ring seal itself is the groove that the o'ring seats into The groove must be designed to accommodate not just the o'ring size, but also its intended usage;10 ORING SEALS – THEORY AND DESIGN PRACTICES Theory An oring seal consists of an oring and a properly designed gland which applies a predictable deformation to the oring The gland is basically a groove dimensioned to a certain height "H" and width "W" (Figure 1) to allow a fixed compression of the oring A common mistake is to design the groove width to "pinch" the oring crosssection, so it is held in the groove The critical design point to keep in mind is homogenous rubber acts like a highly viscous fluid Therefore, the volume is displaced, not compressed A good seal design will provide more gland void than seal volume

How To Use An O Ring In A Non Circular Groove Pattern

O Ring Installation Design And Specification Static Cylindrical Installations Engineers Edge

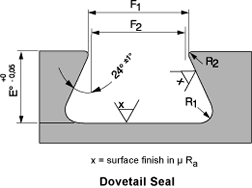

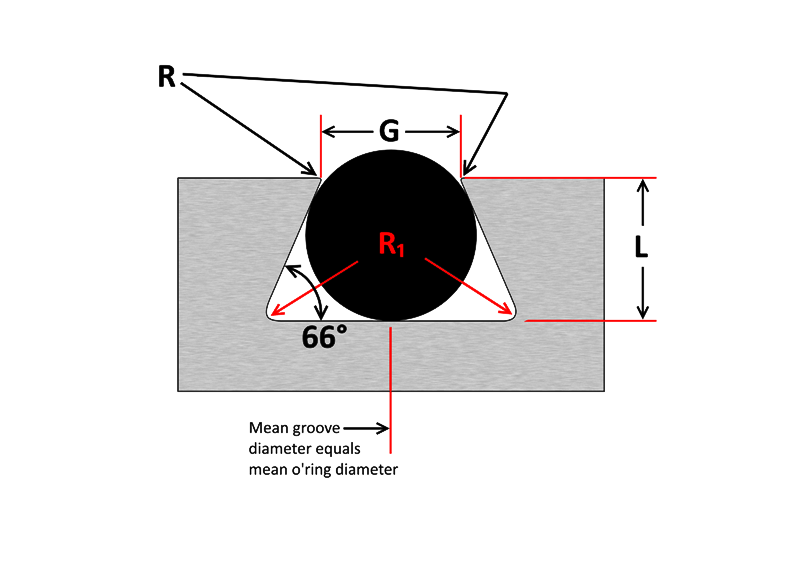

Depending on your application you can have the groove be cut in either the piston or the boreDesign Chart 43 explains how to design an Oring seal when the groove is cut into a fl at surface Note that when the pressure is outward, the groove outside diameter (OD) is primary and the, groove width then determines the inside diameter Conversely, when the pressure is inward, the groove inside diameter is primaryDovetail ORing Gland Design In a dovetail oring gland application the oring squeeze is primarily axial in direction, where a valve exerts force on the top and bottom of the orings surfaces Typically used in static or slow moving applications the dovetail orings gland purpose is to properly hold the oring in place during machine operation

1

Sae J1453 O Ring Face Seal Groove Size Chart Knowledge Yuyao Jiayuan Hydraulic Fitting Factory

If you are designing a face seal, select the ORing with an inside diameter which will position the ORing on the side of the groove opposite the pressure Click here for more information on face seal groove design Note the ORing inside diameter for the next stepBe it dynamic or static operation, radial or axial loading, vacuum or high pressureORing Groove Design 1 The following sizes are not normally recommended for dynamic service, although special applications may permit their use 2 Clearances shown are based on 70 durometer materials The clearances must be held to an absolute minimum consistent with design requirements for temperature variations and should not exceed the

O Ring Wikipedia

O Ring Groove Design Sealing Australia

A surface finish or 16 rms or less is ideal, although rougher surfaces are acceptable if a shorter seal life can be tolerated A radius of 005" on the groove corners is advisable AS568 ORing No Nominal ID Range CrossSection Min Squeeze Groove Width 004 thru 048 5/64" to 43/4"Oring groove design considerations and engineering guides for static face seals, metric orings, static dovetail orings, static rodpiston orings and dynamic rodpiston orings Find the right oring groove design and easily order your oring online from theFor pistontype seals the ID of the Oring should be smaller than the gland diameter so that the installed Oring is always slightly stretched, even with the largest possible Oring ID and smallest possible gland diameter For rodtype seals the OD of the Oring should be slightly larger than the gland diameter so that there is always some

Designing Axial Static O Ring Grooves To Industry Standards Grabcad Tutorials

Untitled Document

The Groove Width GW should therefore be about 15 times the ORing crosssection diameter to accomodate this axial expansion, Design Guidelines for Axial Seals ORing design for axial seals is similar to that for radial seals, with the important points summarized below The ORing must be compressed by a predetermined amount, and thisIt is a elastomer with a round crosssection designed to be seated in a groove and compressed during assembly between two or more parts, creating a seal at the interfaceDovetail grooves are used to hold the Oring in place during installation or maintenance This groove design is relatively uncommon as it is expensive to machine and should not be used unless absolutely required The dovetail groove construction is only recommended for Orings with cross sections of 139 inch (3,53 mm) and larger

O Ring Groove Design Metric Seal Design Inc

Designing Axial Static O Ring Grooves To Industry Standards Grabcad Tutorials

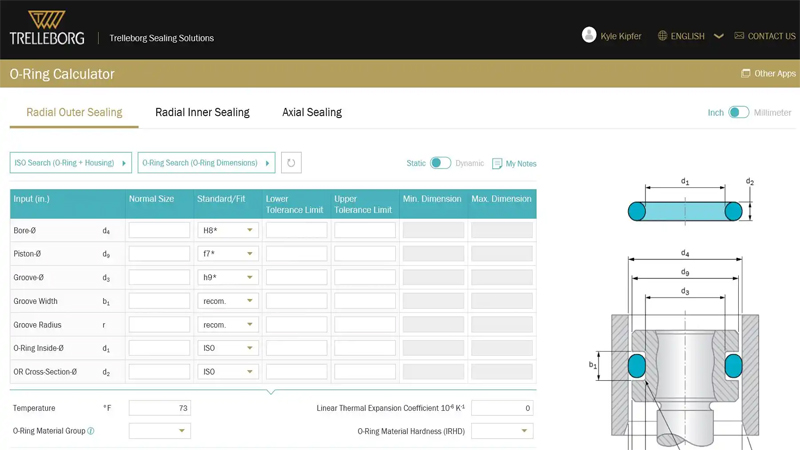

One general guideline for good Oring application and design is to maintain a range of % sqeeze on the Oring (~1040% for static and no more than 30% for dynamic) No less than 75% of the seal crosssection should be contained within the groove to ensure the seal does not "roll" or extrude out of the grooveGroove design guide for static oring face seals provides default recommendations on width, depth, diameter and more for basic applications Oring face seals are used in a variety of applications, including bolted flanges or removable lidsOverview of Seal Design Section The purpose of the Seal Design section is to assist in designing a groove for a specific size oring, to search for possible standard orings for an existing groove or to evaluate an oring in an existing groove The results of

O Ring Groove Dimensions Calculator Precision Polymer Engineering

Dynamic O Ring Design Chart Marco Rubber Plastics Custom O Rings Supplier

Welcome to our Oring Groove Design section Here you will find an Oring groove design guide to help you with your Oring gland dimensions Through our extensive research we believe that these Oring groove dimensions and fit details will provide the optimum Oring compression squeeze for your seal to prevent Oring leaksORing Groove Design ORing Groove design plays an important part in how an oring seals Learn More > Contact World Class;This type of oring flange design is based upon groove OD to limit the side movement of the ORing in the groove due to pressure direction Since the groove width is larger than the cross section of the ORing, then the design should be made for the ORing to have a snug fit on the grooved OD in order to limit ORing movement

Llis

Www Hitechseals Com Includes Pdf O Ring Brochure Pdf

FastDashTM Oring Piston Seal Design Guide Enter the "A" diameter (ie bore diameter), Press the "Submit" button, The appropriate dash no orings will be listed along with their associated groove The OSeal has a round cross section like an Oring However the footprint of the OSeal is designed to match the shape of the groove The primary advantage of the OSeal is custom molding to fit the exact groove, eliminating the concern that comes with bending stress at the corners A smaller corner radii can be used for the groove, allowingThe primary reason for using a Square Ring in a sealing application is that they perform the sealing function in a superior manner – and at a cost lower than any other comparable sealing device For existing applications, there is no need to change the design or procedures Square Rings fit in oring grooves and are interchangeable sizeforsize

O Ring Groove Design Global O Ring And Seal

1

Between 15%25% squeeze on the ORing Static seals can tolerate higher volume swell of the O Ring than dynamic seals B Dynamic seal grooves are normally designed to have about 15% squeeze on the ORing Less squeeze increases probability of leakage while more squeeze increases friction and probability of spiral failureOring groove design is a key consideration in the oring selection process Browse design considerations and recommendations for static face seals, metric orings, static dovetail orings, static rodpiston orings and dynamic rodpiston orings Once you find the right oring groove design you can easily order online from the world's largest oring inventory networkFor a bore (piston) seal QuadRing® Brand Groove Diameter = Max Bore Diameter – (2 X Recommended Gland Depth) For a face seal QuadRing® Brand Groove Depth = Recommended Gland Depth – Application Clearance With a face seal, if the two surfaces to be sealed are in direct contact (such as with a cover), the seal groove depth is simply the

Static O Ring Face Seal Groove Design Guide

Buna O Ring O Ring In Houston And Minneapolis Dichtomatik

O Ring Calculator Ceetak Sealing Solutions

Dynamic Rotary Gland Design Dynamic O Ring Gland

O Ring Groove Design Guides Engineering Quick Reference

O Ring Groove Dimensions Calculator Precision Polymer Engineering

O Rings And Back Up Rings Skf Skf

What Is An O Ring Selection Material And Storage Barnwell

O Ring Groove Design

O Ring Cross Section O Ring Groove Design Data

O Ring Groove Design Sealing Australia

O Ring Groove Design Guides Engineering Quick Reference

Triangular O Ring Grooves Mechanical Seal Engineering Eng Tips

O Ring Seals Roy Mech

How To Use An O Ring In A Non Circular Groove Pattern

Efunda Introduction To O Rings

How To Design An O Ring Groove Vizeng

Gland Design Oringsusa

American Seal Packing General Design And Gland Dimensions

Ficient Design Static O Ring Groove Design Mechanical Engineering

O Ring Groove Design Sealing Australia

Oring Ehandbook

Static O Ring Face Seal Groove Design Guide

Design Of O Ring Seals Ppt Video Online Download

Untitled Document

O Ring Groove Drafting Standards Gd T Tolerance Analysis Eng Tips

Groove Design Quad Ring Seals Minnesota Rubber Plastics

Fact Book Design Guide 4 10

Standard Dovetail Grooves Dovetail Groove Engineering Design Guide

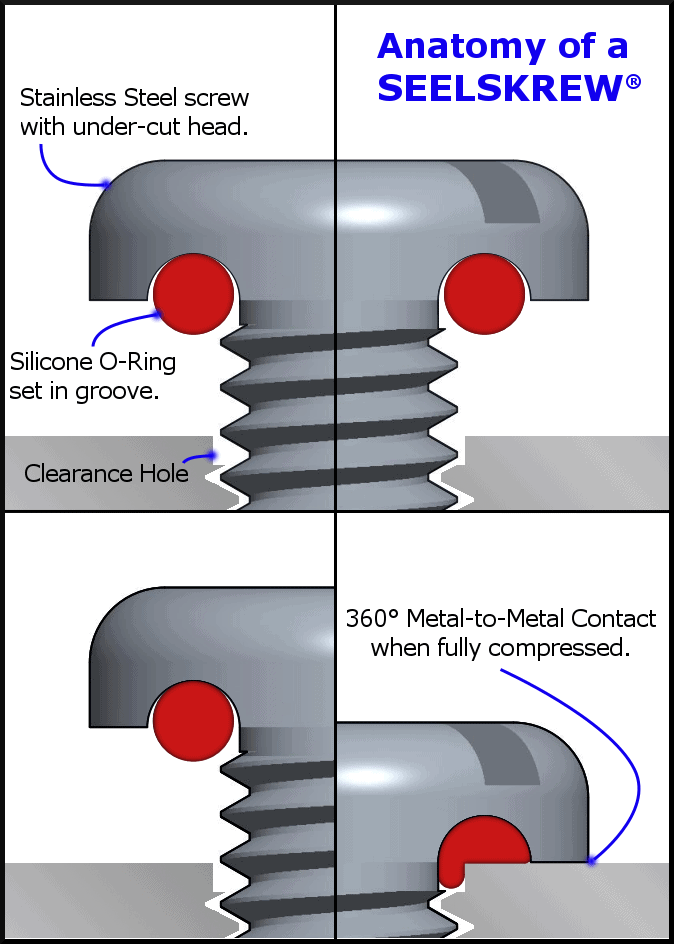

Anatomy Of An O Ring Screw Apm Hexseal Corporation

Groove Design O Ring Seals Minnesota Rubber Plastics

Oring Ehandbook

O Ring Groove Design Global O Ring And Seal

O Rings O Yeah How To Select Design And Install O Ring Seals Tarkka

Seal Design O Ring Design O Ring Design Guide

O Rings O Yeah How To Select Design And Install O Ring Seals Youtube

O Ring

O Ring Groove Design Global O Ring And Seal

Static Axial Internal Pressure Gland Groove Design

Groove Design O Ring Seals Minnesota Rubber Plastics

Seals Eastern Flange Seal O Ring Design Guideline

Www Hitechseals Com Includes Pdf O Ring Brochure Pdf

O Ring Groove Design Seal Design Inc

1

How To Design An O Ring Groove Vizeng

O Ring Calculator Trelleborg Sealing Solutions

O Ring Groove Design Global O Ring And Seal

Oring Ehandbook

O Ring Seals Roy Mech

New Gland Calculator Tool At Applerubber Com Official Apple Rubber Blog

Seals Eastern Plug Seal O Ring Design Guideline

Dovetail Gland Design Dovetail O Ring Groove Dovetail Glands

What You Need To Know About Designing Axial Seals Hot Topics

O Ring Groove Design Dovetail Seal Design Inc

Dovetail O Ring Groove Design Guide A Basic Recommendations

1

Design Of O Ring Seals Ppt Video Online Download

O Ring Groove Design Daemar Inc

O Ring Groove Design Guides Engineering Quick Reference

O Ring Info En O Ring Oring Handbook Eriks Sealingelements Technicalhandbook O Rings Oringapplications Pdf

O Ring Groove Design Rubber Shop

O Ring Groove Calculator O Ring

O Ring Groove Design O Ring Groove Dimensions Mykin Inc

O Ring Groove Design Sealing Australia

Design Of Oring Seals Design Of Oring Seals

Fep O Rings Trelleborg Sealing Solutions

Seal Design O Ring Design O Ring Design Guide

How To Design An O Ring Groove Vizeng

O Ring Groove Design Global O Ring And Seal

O Ring Groove Design Standard As568b Seal Design Inc

4 Common Mistakes In Designing For An O Ring Axial Face Seal Hot Topics

2 Design And Detail Information O Rings Stock O Ring Webshop

O Rings O Yeah How To Select Design And Install O Ring Seals Tarkka

Sealcalc

O Ring Groove Design Guides Engineering Quick Reference

O Rings For Oil Gas Applications Trelleborg

Seals Eastern O Ring Rod Seal Design Guideline

Metric O Ring Groove Design Reference Guide

No comments:

Post a Comment